Learn more about Sialk Industrial Innovators

The Company specializes in producing hollow 3D composite panels (3 to 5 kg/m2) or panels filled with light or heavy mortar, with an extraordinary bending strength and high ratio of strength to weight. These panels offer various novel solutions for a wide range of industrial-technical applications.

The composite panels, stable in terms of dimensions, can also be drilled or cut. Adding fire retardants to the applied resin composition also serves to make the uncovered panels fire resistant.

The Company is capable of producing composite panels of up to 4-meter width, unlimited length, and a thickness of 5 to 32 millimeters.

Sialk Industrial Innovators succeeded in producing 3D fiberglass fabrics with advanced quality, considered high tech, following a decade of vigorous research. It also succeeded in patenting industrial production of these advanced 3D fiberglass fabrics in Iran. Production of such 3D fabrics and panels is limited to only 5 countries in the world.

Sialk Industrial Innovators certificates

Very high bending moment

By maximum distancing of the mass from the center, the composite panels reinforced with 3D woven fiberglass fabrics; bear the following advantages:

high resistance together with extraordinary lightness, maximum bending moment, and maximum increase in strength to weight ratio.

Earthquake-resistant, shock

and fatigue-proof

3D fabrics are resistant to delamination in all X, Y and Z directions, and are immune from fatigue and modes of destruction. The reinforced structure of composites provides for maximum tolerance of bending moment as well as extraordinary resistance against shock and vibration.

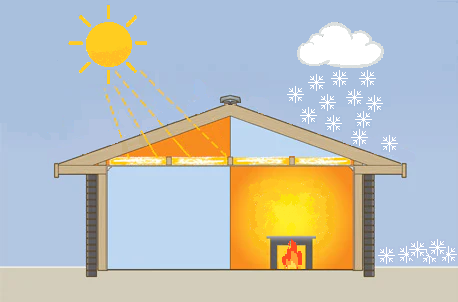

Excellent insulation properties

The central hollow space of Sialk 3D composite panels, filled with thin and low-density fiberglass piles, causes a very low thermal conductivity coefficient (λ=0,08), sound insulation of more than 21 decibels, and high resistance to moisture.

Very light with extreme tolerance

Sialk 3D composite panels, both hollow or filled with cement, offering uniquely specific properties for 3D composite structures, including reduction of the weight of the structure with a high strength-to- weight ratio, has in fact created a revolution in the building industry.

This new and state-of-the-art product, enjoying a high ratio of strength to weight, offers extraordinary advantages for the building industry, especially as load bearing slab and roof/ceiling covering.

The Sialk composite panels, reinforced with 3D fiberglass fabrics, both hollow or filled, possess such unique features as low weight, easy shaping, high strength-to weight ratio, stable coloring, excellent resistance to shock and fatigue, high resistance to rotting and corrosion, and excellent features for thermal and sound insulation. These products offer a wide range of applications in such different fields as load-bearing roof of buildings, Conex boxes, prefab houses with fast construction capability in crisis situations as earthquakes, construction of large reservoirs and pools (water, petroleum and dangerous chemicals), traffic signs, water and sewage manhole hatches, bridges and pedestrian bridges, cover for industrial greenhouses, etc.

These panels offer the following highly competitive advantages:

Sialk products, mainly 3D fiberglass fabrics and various kinds of reinforced composite panels, offers new solutions for various applications of load-bearing components and building structures.

In construction applications, the Sialk composite panels can be widely used as an alternative to reinforced concrete slabs, composite roofs, brick roofs, steel deck roofs, etc. It can also be used as a replacement in various kinds of walls and partitions.

These composite panels enjoy the capability of replacing the other layers (slabs) usually placed on the beams. In this particular application, the composite panels are screwed directly on the beams, serving as a replacement for all the layers usually used (bearing the load and bending, sound and thermal insulation).

In addition to bearing shocks and bending, these panels demonstrate outstanding performance as sound, thermal, and humidity insulation. The existence of millions of fibers in various directions as well as the trapped air between the two layers of the composite panels provides them with the properties suited for effective and proper sound and thermal insulation. The resin shell coated on the composite layers resists moisture penetration for years. Use of these composite panels in hot and humid areas, in addition to high resistance to decay and corrosion, also helps improve the speed of project implementation.

Road, Housing and Urban Development Research Center, Tehran, Iran; as the sole competent national body for issuing the necessary technical certificates, has, upon extensive investigations and conducting technical tests for requisite properties, issued the license for the use of Sialk composite panels as a ceiling structural element.

The Sialk Industrial Innovators, a technology-based company, is committed to provide advanced, innovative, and forward-looking services, commensurate with international standards, at the level of the entire region around Iran.

Central Office

Sales Department

kashan Office